Introduction

The manufacturing industry is undergoing a significant shift, driven by the rapid adoption of digital technologies. For small and medium-sized businesses (SMBs), this shift presents both a challenge and an opportunity. Digital transformation is no longer reserved for large enterprises with massive budgets and tech teams. It's now within reach for businesses of all sizes, including SMBs, and it’s becoming crucial for staying competitive in a global market.

The benefits of digital transformation in manufacturing are numerous and significant for SMBs. From automation in manufacturing to cost savings through digitalization, these advancements are changing how small manufacturers operate.

This article explores how predictive maintenance, data analytics, and supply chain optimization can boost productivity and efficiency for SMBs. We also look into improvements in quality control, sustainability, and real-time monitoring, all of which help SMBs achieve operational performance.

What is Digital Transformation in Manufacturing and Why It's Important for SMBs?

Digital transformation in manufacturing involves the integration of digital technologies to enhance all aspects of the manufacturing process. Companies can implement this approach, using software applications and digitization as the primary drivers. It's a broad business strategy to address traditional challenges and create new opportunities using digital technology.

As the industry grows, digitalization becomes more crucial for SMBs to remain competitive and responsive to market demands. Here are several key concepts that highlight the importance of digital transformation for SMBs:

Industry 4.0

Often referred to as the fourth industrial revolution, Industry 4.0 represents the intersection of digital and physical systems. This transformation is characterized by significant advancements in technologies like the Internet of Things (IoT), cloud computing, artificial intelligence (AI), and data analytics. One of the key drivers of Industry 4.0 is smart manufacturing. Smart Manufacturing uses advanced cyber technologies, big data analytics, and automation to create an efficient, adaptive, and intelligent manufacturing process.

For SMBs, adopting Industry 4.0 technologies leads to:

- Optimization of operational efficiency through automation and smart manufacturing.

- Higher product quality by using real-time data and predictive analytics to identify potential defects before they impact production.

- More flexibility and responsiveness to market changes, to quickly adjust production based on demand.

By integrating these technologies, SMBs can optimize resource utilization, reduce waste, and streamline processes to meet customer needs more effectively. According to a Gartner report, by 2027, 50% of manufacturers will use AI technologies for lifecycle management, up from less than 5% in 2023. This highlights the growing importance of Industry 4.0 for businesses of all sizes.

Data Analytics & Business Intelligence (BI)

Data Analytics and Business Intelligence (BI) are critical tools for SMBs to make informed decisions based on real-time information rather than intuition or guesswork. These technologies allow manufacturers to analyze significant amounts of data to gain insights into operations, market trends, and customer behavior.

The benefits of Data Analytics & BI for SMBs include:

- Informed decision-making: SMBs can use real-time data to optimize production schedules, reduce downtime, and respond quickly to market fluctuations.

- New customer insights: Businesses can optimize products and services to meet demand more precisely by analyzing customer behavior patterns.

- Supply chain optimization: Data analytics can help SMBs track and manage inventory more effectively, reducing overstocking and ensuring that the right products are available at the right time.

Implementing data-driven strategies allows SMBs to be more proactive, adjusting production processes based on insights rather than reacting after the fact. This leads to better efficiency, improved profitability, and a stronger competitive position.

Automation

Automation plays a key role in digitalization by utilizing software and machinery to handle repetitive tasks. This shift reduces reliance on manual labor, minimizes errors, and accelerates production timelines. For SMBs, automation offers several critical benefits:

- Higher productivity: Automated systems can operate 24/7, boosting output without requiring extra labor.

- Error reduction: Automation improves reliability, reducing the risk of costly mistakes.

- Workforce optimization: By automating routine tasks, businesses can free up employees to focus on higher-value activities like innovation and customer engagement.

According to the latest report, 54.5% of SMBsbelieve digital tools allow them to compete more effectively with larger firms. Therefore, to maximize the value of digital transformation, manufacturers must understand its essential components.

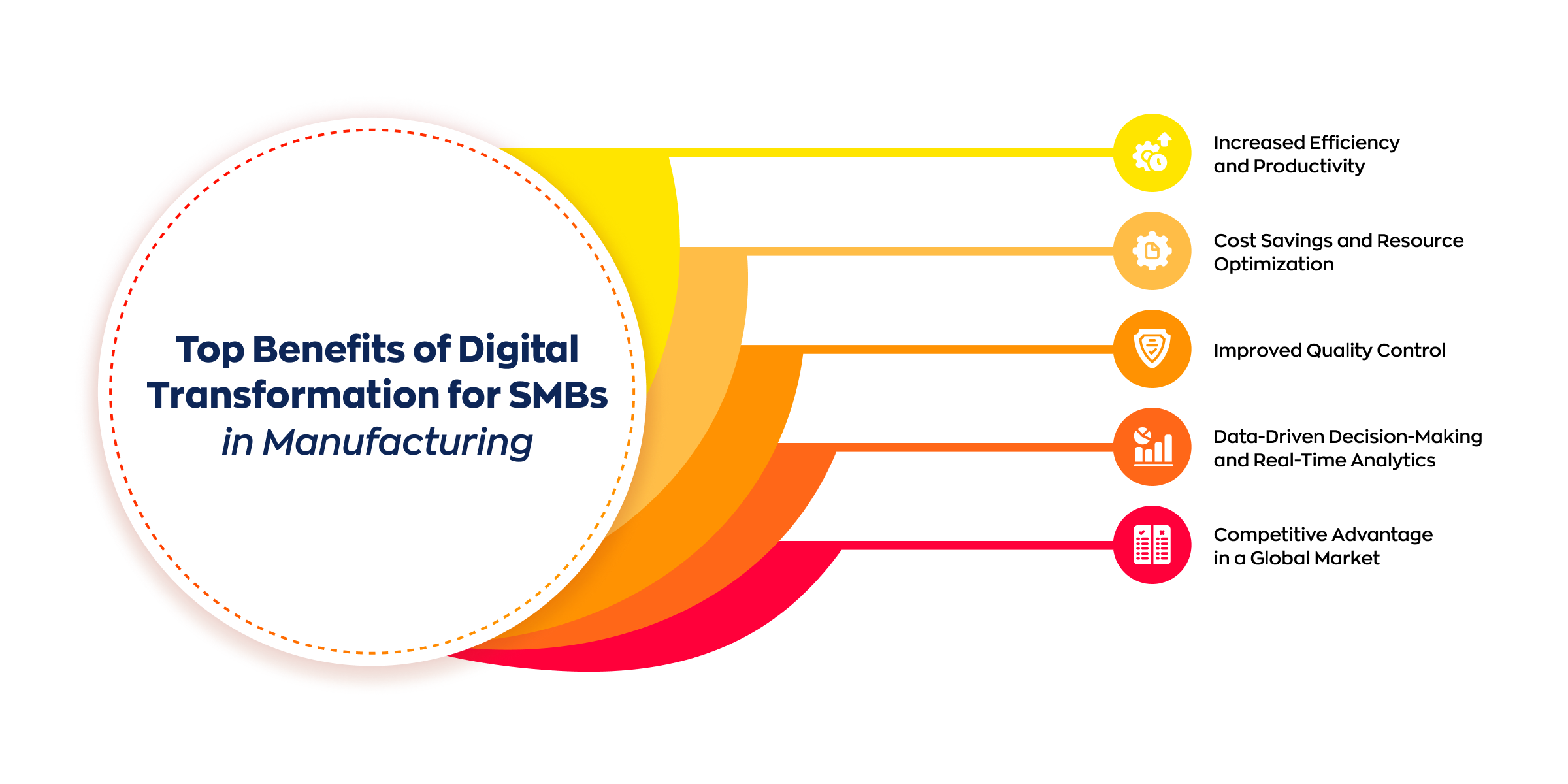

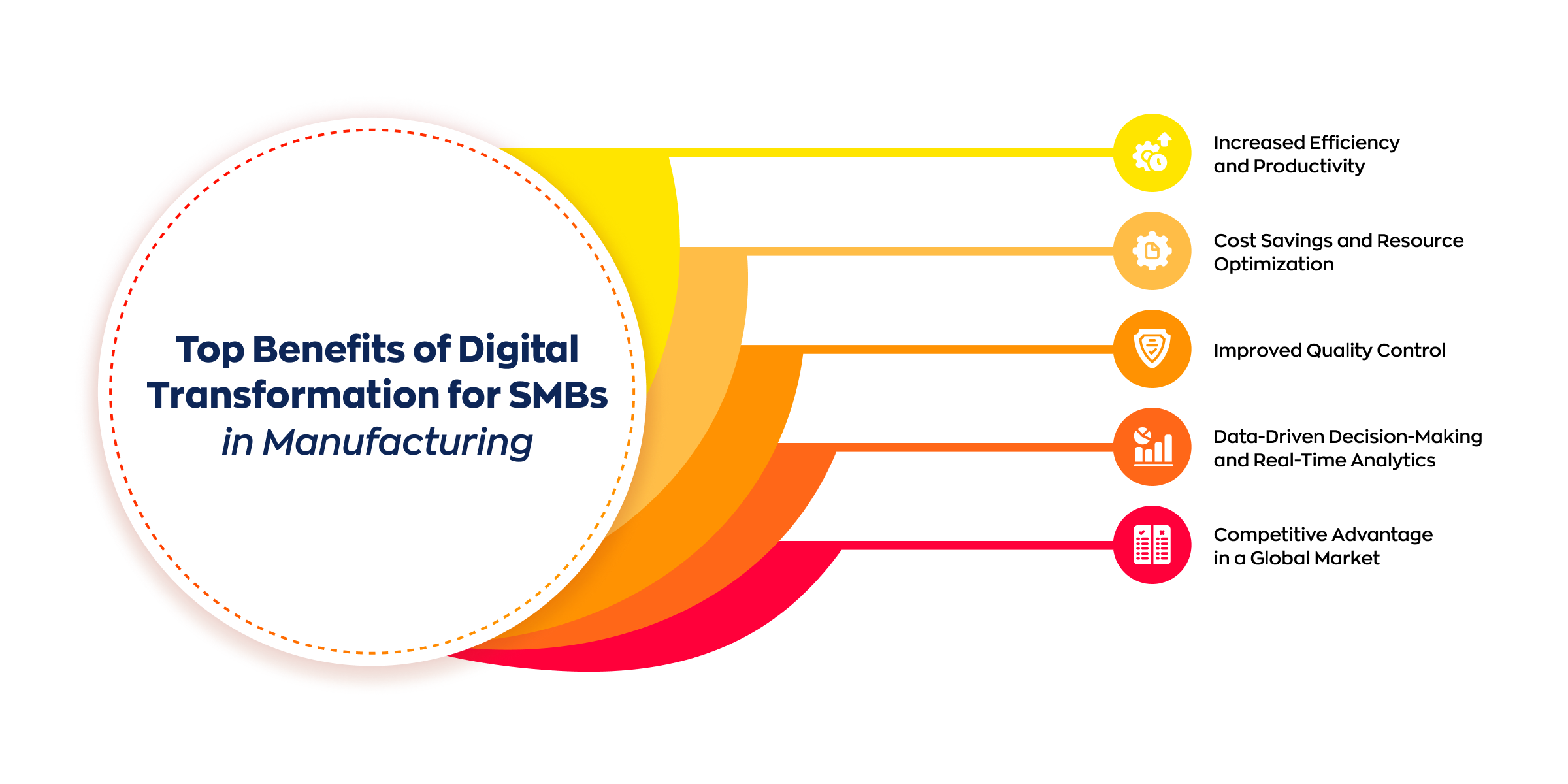

Top Benefits of Digital Transformation for SMBs in Manufacturing

Digital transformation offers several manufacturing advantages for small and medium-sized businesses (SMBs). By adopting smart technologies and digital tools, these companies can enhance their operations and compete more effectively in the global market.

Increased Efficiency and Productivity

For SMBs in manufacturing, boosting productivity without increasing costs is a constant challenge. IDC reports, that 24.3% of manufacturers now prioritize productivity and efficiency as key objectives in their digital transformation strategies. One of the most effective ways to achieve this is through automation, a core element of Industry 4.0 technologies that can drive significant improvements in operations.

Automation tools like robotic process automation (RPA) and AI-driven systems streamline repetitive tasks and reduce the need for manual intervention.

Even small efficiency improvements can accumulate into significant gains over time, and many of these digital technologies are extremely useful and affordable for SMBs. For example, Custom Enterprise Resource Planning (ERP) solutions, offer an all-in-one platform to manage everything from production to finance, providing real-time insights into operations. This allows manufacturers to move beyond manual tracking of production data and instead rely on digital systems that provide instant access to performance metrics.

Actionable Tip: Begin by identifying manual, repetitive tasks in your production process that you should automate.

Cost Savings and Resource Optimization

One of the most interesting reasons for SMBs to adopt digital transformation is the potential for cost savings. By automating routine tasks, optimizing resource usage, and improving supply chain management, SMBs can significantly decrease expenses and boost profits.

A major driver of these cost savings is the Internet of Things (IoT). IoT-enabled devices and systems allow manufacturers to collect real-time data from their equipment, processes, and supply chains. This data-driven approach leads to smarter, more efficient operations. For instance, predictive maintenance uses IoT sensors and data analytics to monitor machinery in real-time, predicting when maintenance is needed before a failure occurs. Recent research has indicated that this strategy can cut maintenance expenses by up to 20-30% while at the same time increasing equipment durability.

Businesses also use IoT to manage resources efficiently. Smart sensors can monitor energy usage in the various stages of production. Analyzing this data enables SMBs to identify inefficiencies, such as machinery using excessive energy or production stages wasting energy. Beyond energy savings, IoT plays a critical role in improving supply chain management. With IoT-powered real-time tracking of materials, products, and assets, businesses gain greater visibility across their entire supply chain. This degree of accuracy is useful in managing inventories effectively and minimizing cases of overstocking and other associated costs.

Another key advantage is asset tracking. IoT-based systems enable SMBs to monitor the location and condition of valuable equipment and products throughout the supply chain. This real-time data helps prevent loss, delays, and misplacement while optimizing logistics. As a result, businesses can lower storage expenses and free up capital tied to unsold goods, all while keeping operations running smoothly.

Actionable Tip: Implement a small-scale predictive maintenance system to monitor your most critical equipment. This can prevent significant downtime and extend the lifetime of your machinery.

Improved Quality Control

Maintaining consistent product quality is essential for SMBs in manufacturing, where even minor defects can lead to expensive replacements and disappointed customers. Manufacturing digitalization is crucial for improving quality control through real-time data, and advanced analytics, and to monitor production and address issues.

One of the most impactful technologies in this space is digital twins. By creating virtual models of products and processes, manufacturers can simulate production environments and identify potential quality issues before physical production begins. This innovative approach not only improves product quality but also minimizes material waste and reduces the need for costly adjustments during production.

Smart manufacturing also allows for continuous quality monitoring during production. By using real-time data to track performance, manufacturers can identify defects early and take appropriate actions immediately. This real-time data is collected at every stage of manufacturing, allowing businesses to catch defects as soon as they occur and take corrective actions immediately. This reduces the likelihood of defects reaching customers and ensures a consistent, high-quality output.

Predictive analytics is another powerful tool for improving quality. By analyzing data from previous production runs, businesses can predict when and where defects are most likely to occur. This allows them to take preemptive measures, reducing the occurrence of defects and maintaining high standards of product quality.

Actionable Tip: Implement a basic digital twin of a critical process in your production line. This will help you identify and fix potential quality issues before they impact your final product.

Data-Driven Decision-Making and Real-Time Analytics

Digital transformation empowers SMB manufacturers to make precise, data-driven decisions grounded in real-time information instead of outdated assumptions.

With the right Data Analytics & BI solutions, businesses can access the full potential of their data.Real-time data analyticshas become a powerful tool for monitoring production performance. This proactive approach leads to significant reductions in downtime, and improved workflow

Beyond the production floor, big data analysis provides valuable insights into customer behavior patterns and market demand cycles. This deeper understanding enables SMBs to optimize production scheduling, ensuring they produce the right products at the right time. By matching supply with actual demand, businesses can reduce waste, minimize overproduction, and create a more responsive and efficient manufacturing process. Manufacturers can gain actionable insights through Data Analytics & BI services that lead to smarter decision-making and better outcomes.

Even a small electronics manufacturer might use real-time analytics to detect a recurring quality issue in a specific production step. By addressing this issue promptly with the support of tailored data analytics tools, they can not only improve product quality but also prevent costly rework and potential customer dissatisfaction. Moreover, careful analysis of market trends may reveal periods of rising demand for particular products. This foresight allows manufacturers to adjust production schedules proactively, thereby avoiding overstocking and subsequently reducing storage costs.

Actionable Tip: Begin by implementing data analytics in a key area, such as production monitoring or inventory management. As you see the benefits, gradually expand these tools to other areas of your business to unlock deeper insights and drive continuous improvement.

Competitive Advantage in a Global Market

Digital transformation offers SMBs a powerful tool to enhance their competitive advantage in today’s global market. By adopting digital technologies, SMBs can respond more quickly to shifting market trends, allowing them to stay ahead of the competition. Real-time data analysis enables businesses to adapt to changing customer demands, optimize production schedules, and launch new products faster.

Additionally, digital transformation enables product customization at scale, allowing SMBs to meet specific customer preferences. This level of personalization not only increases customer satisfaction but also helps businesses differentiate themselves in a crowded marketplace. By offering tailored products and services, SMBs can carve out a niche that appeals to customers seeking unique solutions.

Moreover, digital tools empower SMBs to provide better customer service. Automation, CRM systems, and AI-driven chatbots streamline communication, ensuring faster responses and a more seamless customer experience. This enhanced service builds stronger customer relationships, driving loyalty and repeat business, which is essential in a competitive global environment.

As a result of digitalization, small and medium businesses are improving their efficiency, reducing costs, and maintaining market orientation and flexibility in the global economy. All these factors are important in achieving the organization's long-term development and sustainability.

Key Challenges and Solutions in Digital Transformation for SMBs in Manufacturing

In manufacturing, small and medium-sized businesses (SMBs) face unique challenges when attempting to embrace digital transformation. While large manufacturers have made significant strides, many SMBs are still grappling with this transition. According to IDC, 92% of SMBs budget for digital transformation, and 76% dedicate staff to these efforts. However, smaller SMBs face distinct obstacles, particularly in adding dedicated staff and resources compared to their larger counterparts. These challenges show the need for SMBs to address these barriers head-on to maintain competitiveness and ensure long-term success.

Here are the key challenges SMBs face in digital transformation, along with practical solutions:

1. Resource Constraints

Challenge: SMBs often face the task of finding the right-sized digital solutions that fit their current resources and business objectives. The misconception that digital transformation requires massive upfront investments can make some businesses hesitant to start their journey.

Solution: Scalable and Flexible Approaches: SMBs can embrace digital transformation through various cost-effective and scalable solutions.

- Low-Code Platforms: These allow businesses to build custom applications without extensive technical knowledge, significantly reducing development costs and time.

- Cloud-Based Services: Pay-as-you-go models provide access to enterprise-level tools without large upfront investments in infrastructure.

- Open-Source Tools: Many powerful digital tools are available as free, open-source options, requiring only the investment of time to implement.

- Phased Implementation: Start with small, high-affected projects and slowly expand. This approach allows for learning and adaptation with minimal initial investment.

The key concept is to start with solutions that address immediate needs while laying the groundwork for future expansion.

2. Talent and Skill Development

Challenge: SMBs often find themselves competing with larger organizations for digital talent. The rapidly evolving technological landscape requires specialized skills that can be challenging to develop or attract on a limited budget.

Solution: Strategic Talent Acquisition and Development.

- Partnerships and Outsourcing: Collaborate with outsourcing providers or digital transformation consultants to access specialized expertise without the need for full-time hires.

- Upskilling Programs: Invest in targeted training programs to develop digital skills within your existing workforce.

- Flexible Work Arrangements: Attract skilled professionals by offering flexible work options, which can be particularly interesting to digital natives and experienced consultants.

By combining these strategies, SMBs can build a capable digital team that grows with the company's transformation journey.

3. Identifying Digital Transformation

Challenge: The perception of digital transformation as a complex, complete process can be overwhelming for SMBs, leading to difficulties in taking the first steps.

Solution: Practical Education and Incremental Approach.

- Customized Roadmaps: Develop a tailored digital transformation plan that aligns with your specific business goals and resources.

- Start Small, Think Big: Begin with high-impact, low-risk projects that demonstrate tangible benefits, such as automating a single manual process.

- Peer Learning: Engage with industry associations or local business groups to learn from the experiences of similar-sized companies.

- Digital Transformation Workshops: Organize or attend workshops that break down the process into actionable steps, demystifying the journey.

- Leverage Free Resources: Take advantage of online courses, webinars, and resources offered by technology providers to build internal knowledge.

By breaking down digital transformation into manageable steps and leveraging available resources, SMBs can confidently embark on their digital journey.

4. Ensuring Data Security and Trust

Challenge: As digital adoption increases, so does the need for robust data security measures, which can be daunting for SMBs with limited IT resources.

Solution: Proactive and Scalable Security Measures.

- Cloud Security: Leverage the advanced security features offered by reputable cloud service providers, which often exceed what SMBs can implement on their own.

- Employee Training: Implement regular cybersecurity awareness training to create a security-conscious culture.

- Phased Security Implementation: Start with fundamental security measures like multifactor authentication and regular backups, gradually building a comprehensive security posture.

- Security Audits: Conduct periodic security assessments to identify and address vulnerabilities proactively.

- Compliance Frameworks: Adopt industry-standard security frameworks as guidelines for implementing best practices.

- Incident Response Plan: Develop and regularly test a plan for responding to potential security incidents, ensuring quick and effective action if needed.

By prioritizing security from the start, SMBs can build trust in their digital initiatives and protect their valuable data assets.

The Future of Digital Transformation for SMBs in Manufacturing

The future of digital transformation for small and medium-sized businesses (SMBs) in manufacturing is promising, with technology becoming more accessible and affordable.

Also, the cost of data collection and analytics decreases, even small companies can gather meaningful information to guide their decisions. This ability to harness data allows SMBs to optimize their operations, improve product quality, and better serve their customers. Data-driven decision-making will become increasingly crucial in the manufacturing industry, enabling SMBs to remain agile and respond quickly to changing market conditions.

AI Analytics and IoT Integration

In the near future, we can expect to see more SMBs utilizing AI-powered analytics to gain real-time insights into their operations. From predicting demand fluctuations to optimizing production schedules, AI will empower small manufacturers to make smarter, faster decisions that boost efficiency and reduce waste. Moreover, the integration of AI with IoT devices will allow for even deeper levels of automation, further improving productivity and reducing the need for manual intervention.

Digital Twins

Another promising technology for small and medium-sized businesses is digital twins, which are digital replicas of real objects or systems. Digital twins allow modeling the manufacturing processes or equipment and experimenting with changes to see what can go wrong in a virtual environment rather than in real life. This reduces risks and allows businesses to operate better. It also minimizes time loss.

Green Manufacturing and Sustainability

Another important key trend in the future of digital transformation is the increasing importance of sustainability. Consumers and regulators are placing growing pressure on manufacturers to adopt eco-friendly practices.

The digital transformation process offers valuable opportunities for small and medium-sized businesses to improve their environmental performance. These businesses can effectively monitor and reduce their environmental footprint by optimizing energy usage, minimizing waste, and implementing sustainable sourcing practices.

As highlighted in the Gartner report, the industrial manufacturing sector is undergoing a significant shift towards sustainability, driven by the need to reduce carbon emissions and increase the use of green energy. By 2026, it is projected that 70% of manufacturers will transition to comprehensive application lifecycle management (ALM) platforms, which will help streamline processes and enhance sustainability efforts. This transition is critical as it allows manufacturers to manage their resources more effectively and implement sustainable practices throughout their operations.

Cloud-Based Platforms

Even more importantly, cloud-based platforms will play an increasingly significant role in the digital transformation of SMBs. Cloud technology allows manufacturers to store, manage, and access their data remotely, providing greater flexibility and scalability. This is particularly beneficial for SMBs with limited IT resources, as cloud solutions offer enterprise-grade tools without the need for costly infrastructure investments. As cloud adoption continues to grow, SMBs will be able to collaborate more effectively with partners, suppliers, and customers, driving innovation and improving operational efficiency.

5G Connectivity

Finally, 5G connectivity will revolutionize digital transformation for SMBs by enabling faster, more reliable communication between devices, machines, and systems. With 5G, manufacturers can implement advanced IoT solutions that require low latency and high bandwidth, such as autonomous mobile robots or real-time remote monitoring. This enhanced connectivity will allow SMBs to operate more seamlessly, scale their operations, and compete on a stage.

Key Strategies for SMBs to Stay Competitive in Digital Manufacturing

- Identify High-Impact Areas and Develop a Clear Strategy

- SMBs should pinpoint where digital technology can create the most straightforward impact.

- Outlining specific goals and actionable plans will help ensure focused efforts in achieving successful digital transformation.

- Foster a Digital Culture and Embrace Data Analytics

- It is important to promote change and to help employees embrace and implement new technologies in the process of digital transformation.

- By using data analytics to gain customer insights and optimize supply chain management, SMBs can reduce losses and prepare for potential disruptions.

- Leverage Cloud Technology and Explore Low-Code Applications

- Cloud services are convenient, as they are easily scalable and adaptable to the needs of SMBs, which need to improve data protection and compliance.

- Low-code applications provide versatile tools that can streamline workflows, from visual inspection of machinery to automating various business processes.

- Enhance Operational Efficiency Through Automation

- The application of automation results in a decrease in the number of manual activities performed, which again improves efficiency and minimizes mistakes.

- By integrating automated solutions, SMBs can focus on higher-value activities that drive growth and innovation

As SMBs continue to adopt digital technologies, they are likely to see improved productivity, better customer service, reduced errors, and enhanced reporting capabilities. The future of manufacturing for SMBs lies in embracing these digital tools and strategies to remain competitive and responsive to market demands.

Conclusion

Digital transformation is transforming the manufacturing landscape, providing small and medium-sized businesses with unique opportunities to succeed in an increasingly competitive market. By harnessing cutting-edge technologies and innovative digital solutions, SMBs can:

- Boost efficiency and reduce operational costs

- Bring product quality to new levels

- Make informed and quick decisions based on data.

- Adapt swiftly to growing customer demands

- Compete on the playing field with larger industry players

For SMBs ready to get started on their digital journey, the key is strategic implementation.

Start with high-impact, cost-effective solutions that deliver immediate ROI. Develop a forward-thinking company culture that promotes innovation and invests in upskilling your workforce. Remember, digital transformation isn't just about adopting new tech–it's about future-proofing your business. By taking a measured, step-by-step approach, even small manufacturers can benefit from the transformative power of digital tools.