Introduction

Today, we’re witnessing a revolution in manufacturing, and it's all thanks to the Internet of Things (IoT). As we dive into the world of digital transformation, we see how IoT in manufacturing is changing the game. Manufacturing is adopting new technologies such as wireless sensors, cloud computing, embedded systems, and big data, which has led to the fourth industrial revolution known as Industry 4.0.

The key objective is to make things smarter, faster, and more effective. Therefore, manufacturers adopt IoT to remain competitive in a hyper-competitive market.

In this article, we'll explore how IoT is used in manufacturing and the benefits it brings. We'll dive into how predictive maintenance cuts downtime and saves money, and how real-time monitoring boosts operational efficiency. By the end, you will clearly understand how the Internet of Things is transforming the future of manufacturing and why it is a vital tool for businesses that want to stay ahead and improve their business operations.

Understanding IoT in Manufacturing

The Internet of Things (IoT) has revolutionized numerous industries, but its impact on manufacturing is especially significant. At its core, IoT in manufacturing refers to the use of interconnected devices and systems that collect, exchange, and analyze data to optimize industrial processes. When it's used in manufacturing, it's called the Industrial Internet of Things (IIoT).

Definition of IoT and IIoT

IoT is a network of physical devices embedded with sensors, software, and other technologies to connect and exchange data with other devices and systems over the internet.

In manufacturing, IIoT takes this concept a step further by integrating it into industrial environments. It combines traditional machinery and processes with advanced digital technologies. It enables manufacturers to automate operations, reduce downtime by 50%, and improve decision-making through real-time data analysis. The integration of IoT technologies improves operational productivity and highlights the significant benefits of digital transformation in manufacturing, which are extremely important for staying competitive in this market.

Manufacturing has several key components that make up the backbone of IoT:

- Sensors: These are the primary data collection tools in IoT and IIoT systems. They monitor various parameters such as temperature, pressure, and machine performance, providing crucial data for predictive maintenance and quality control.

- Connectivity: Devices and sensors are interconnected through robust communication networks, allowing seamless data flow between machines and systems. Technologies such as 5G, Wi-Fi, and industrial Ethernet are commonly used to deliver reliable and high-speed data transmission.

- Data Analytics: Advanced analytics are used to process and interpret the information. This helps manufacturers gain insights into operational performance, detect problems, and predict future trends based on data.

- Cloud Computing: Cloud platforms store and manage vast amounts of data generated by IoT devices. They create fast infrastructure and extensive processing that support real-time data operation and maintain a consistent information management system for manufacturers.

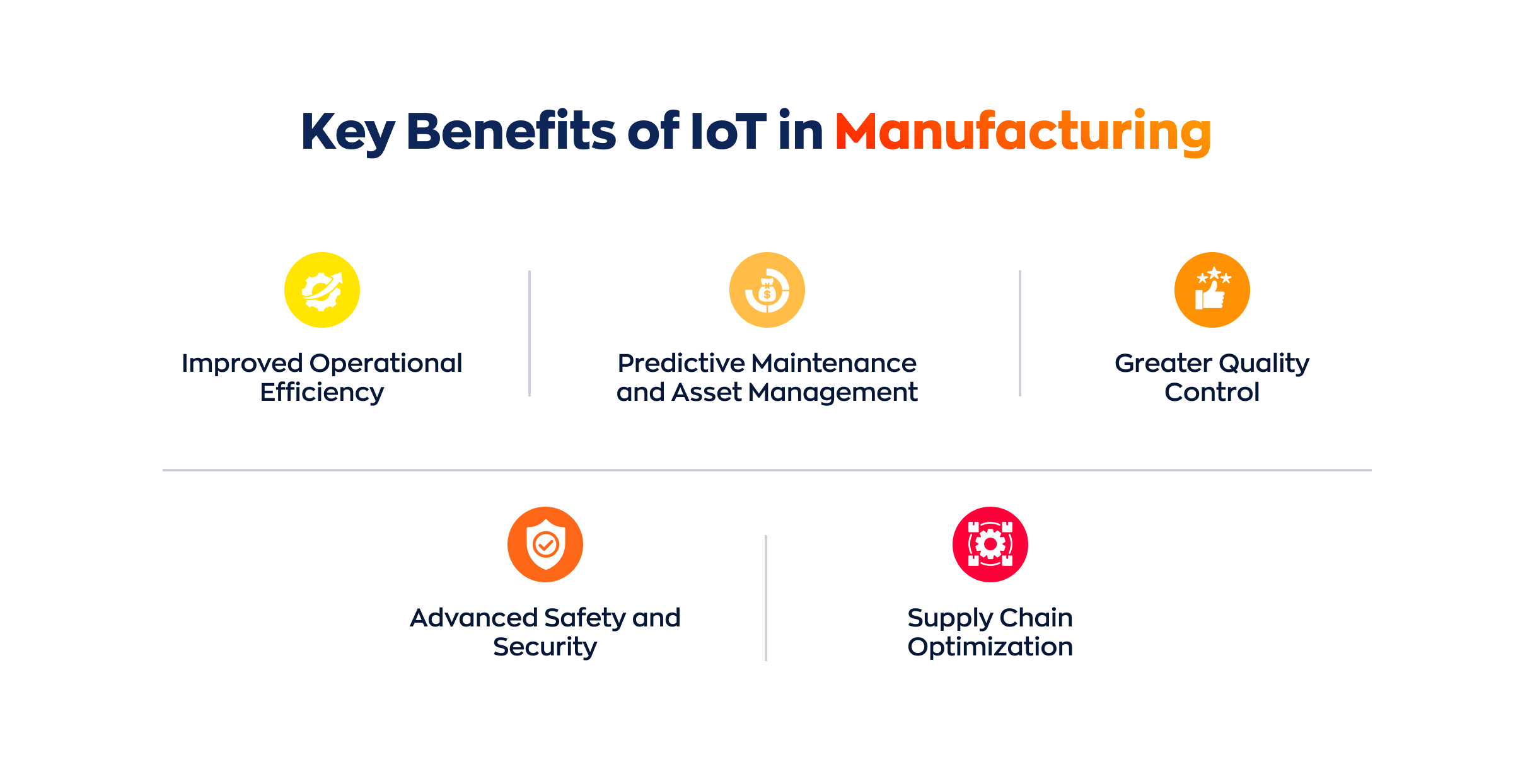

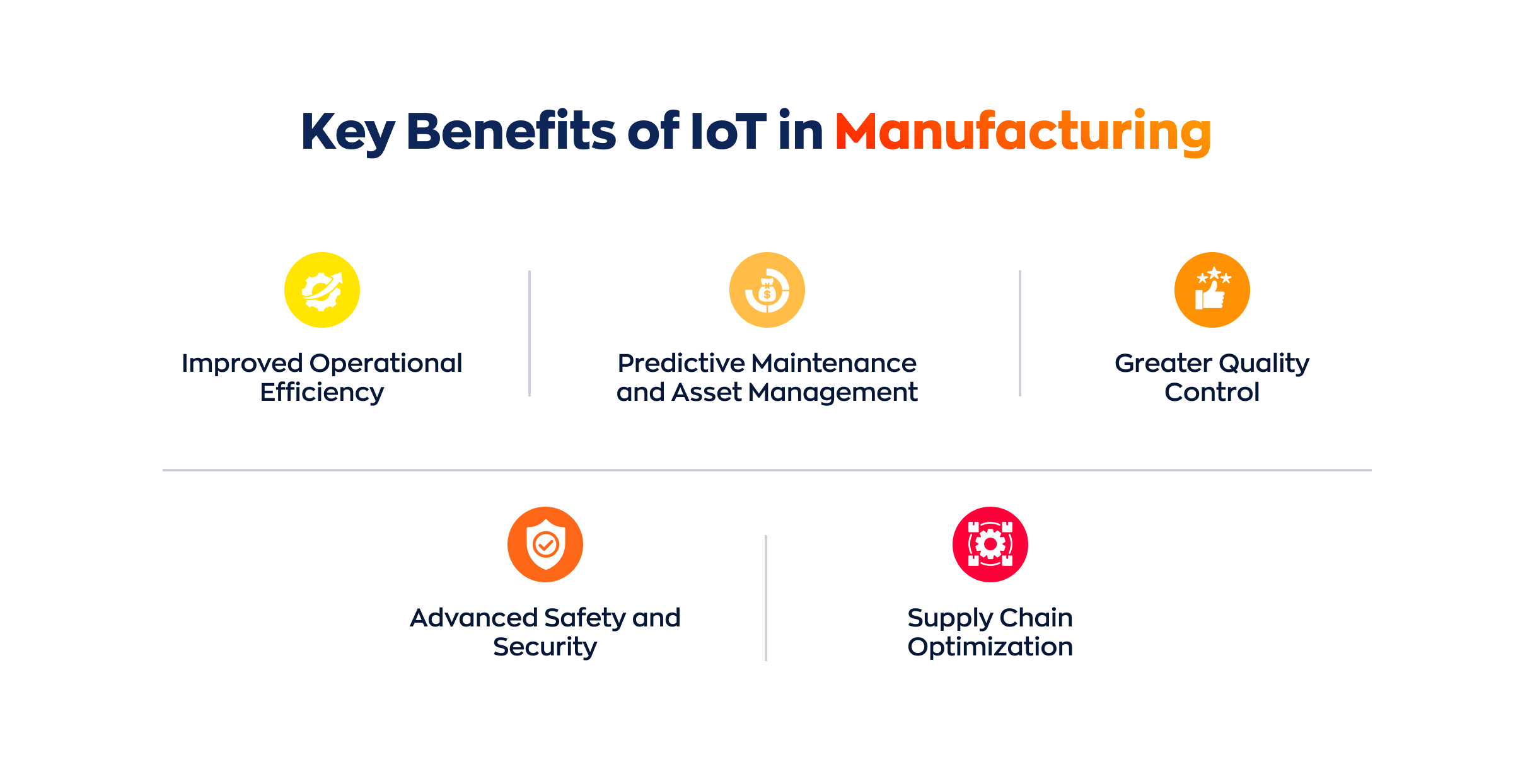

Key Benefits of IoT in Manufacturing

Improved Operational Efficiency

One of the most significant advantages of implementing IoT in manufacturing is the increase in operational efficiency. According to the comprehensive research, 80% of C-suite level highlight the importance of integrating IIoT for their company.

Real-time monitoring and data-driven decision-making help manufacturers better manage themselves and identify inefficiencies that would have otherwise been missed. Continuous data from IoT sensors on production performance helps manufacturers optimize their workflows and keep operations running smoothly.

The best thing about IoT is that it also optimizes the production process by revealing the performance and bottlenecks of the equipment. For example, manufacturers can adjust production schedules, allocate resources more efficiently, and reduce energy consumption with high productivity levels, depending on the machine outputs in real-time.

Reduction in manual errors is another key advantage of IoT implementation. By automating repetitive tasks and using real-time data, manufacturers can minimize human intervention in critical areas, thus lowering the risk of operational downtime and ensuring that production continues without unexpected halts.

Predictive Maintenance and Asset Management

IoT also enables a shift from traditional reactive maintenance to predictive maintenance. In a reactive maintenance model, companies only address equipment issues after they occur, leading to significant downtime and costly repairs. Based on the research, 43% of SMEs use outdated inventory tracking methods, which signifies the importance of integrating IoT in the manufacturing process. However, with IoT-enabled real-time equipment health monitoring, manufacturers can predict when machinery is likely to fail, allowing for maintenance to be scheduled proactively.

This predictive maintenance approach reduces the risk of unplanned downtime and significantly lowers maintenance costs. By monitoring critical equipment parameters such as vibration, temperature, and pressure, IoT systems can alert operators to potential issues before they escalate, ensuring that repairs are made at the most optimal time.

Moreover, IoT solutions make asset management more efficient. Manufacturers can track machine performance and condition in real-time, improving asset lifespan and utilization.

Greater Quality Control

Quality control is another area where IoT in manufacturing makes a difference. By enabling real-time defect detection, manufacturers can identify quality issues early in the production process, preventing defective products from reaching customers. Sensors placed at various stages of the production line capture data related to product dimensions, weight, and other key quality metrics.

The integration of digital twins further improves process optimization. Digital twins are virtual replicas of physical assets or production processes that allow manufacturers to simulate different scenarios and detect potential flaws before they manifest in the actual production environment. This proactive approach improves quality and reduces waste.

According to the GE Digital Industrial Evolution Index, 78% of manufacturing companies identify increasing operating efficiency as a top benefit of Digital Industrial Transformation, highlighting the multifaceted impact of IoT technologies in the manufacturing sector.

Advanced Safety and Security

Safety and security are critical in manufacturing environments, and IoT helps to maximize workplace safety by automating environmental monitoring. IoT sensors can monitor dangerous conditions such as temperature extremes, gas leaks, or equipment failures, and send real-time alerts.

Furthermore, connected devices play a major role in preventing security breaches. By continuously monitoring environmental conditions and automating safety measures, IoT ensures compliance with industry-specific safety regulations. It raises the safety of its workers and helps the manufacturers who use it to avoid hefty penalties and legal cases arising from noncompliance with the set rules and regulations.

Supply Chain Optimization

Manufacturing with the help of IoT enables the real-time visibility of the supply chain, where manufacturers can monitor the flow of materials, products, and inventory during the entire process. This visibility is crucial, as supply chain disruptions can have significant financial implications. The increased cost of working is the leading consequence of supply chain disruptions, affecting 84.6% of cases. Therefore, regular tracking through IoT allows for the proper placement of materials at the right time and helps mitigate these costly disruptions.

Moreover, IoT data can significantly impact demand forecasting and production planning. By analyzing trends in real-time, manufacturers can adjust their operations to meet changing customer demand and minimize the risk of surpluses.

Finally, IoT provides better visibility across the supply chain, allowing manufacturers to monitor supplier performance, optimize logistics, and reduce lead times. With better insight into each stage of the supply chain, manufacturers can make informed decisions, reduce waste, and improve overall efficiency in delivering products to the market.

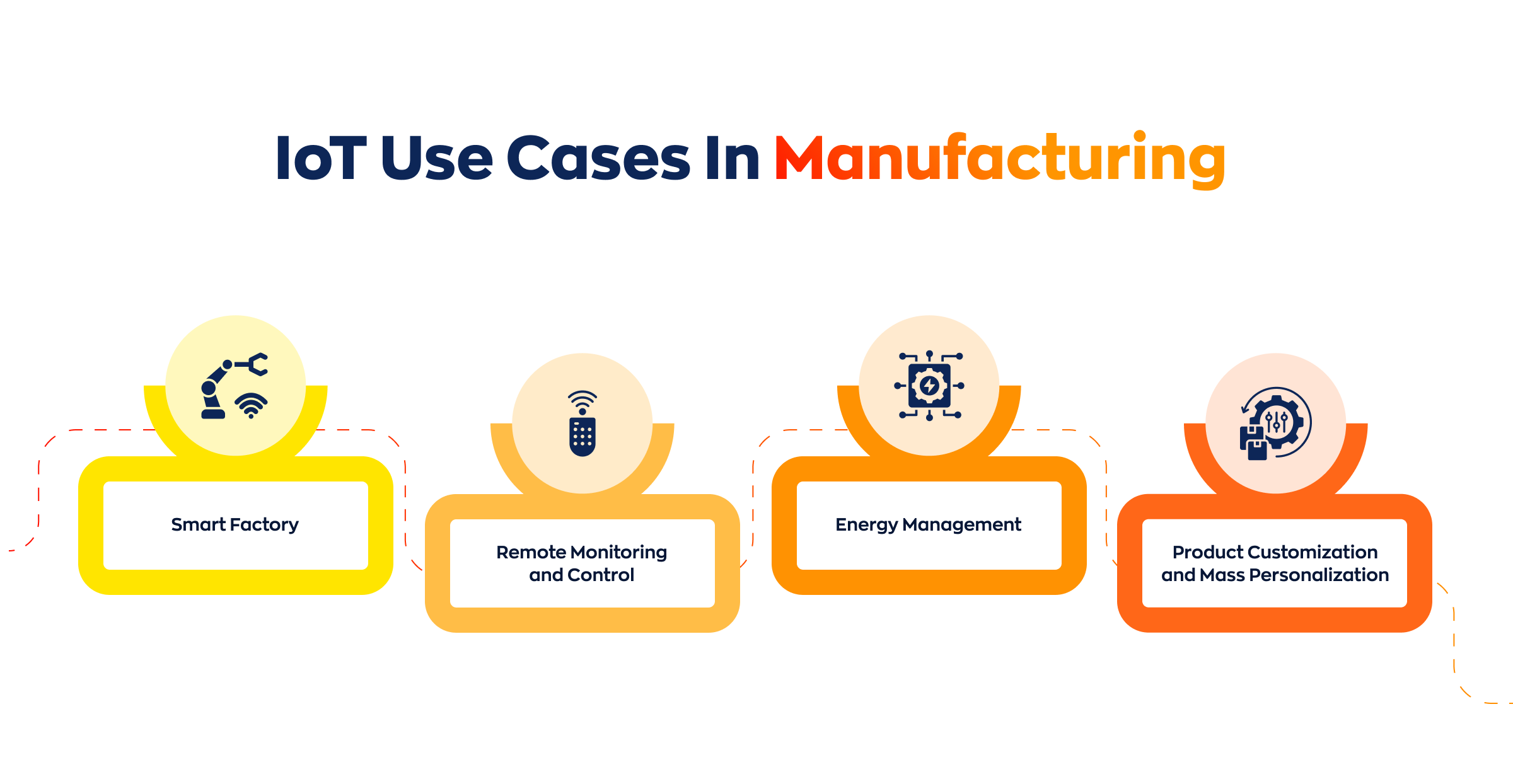

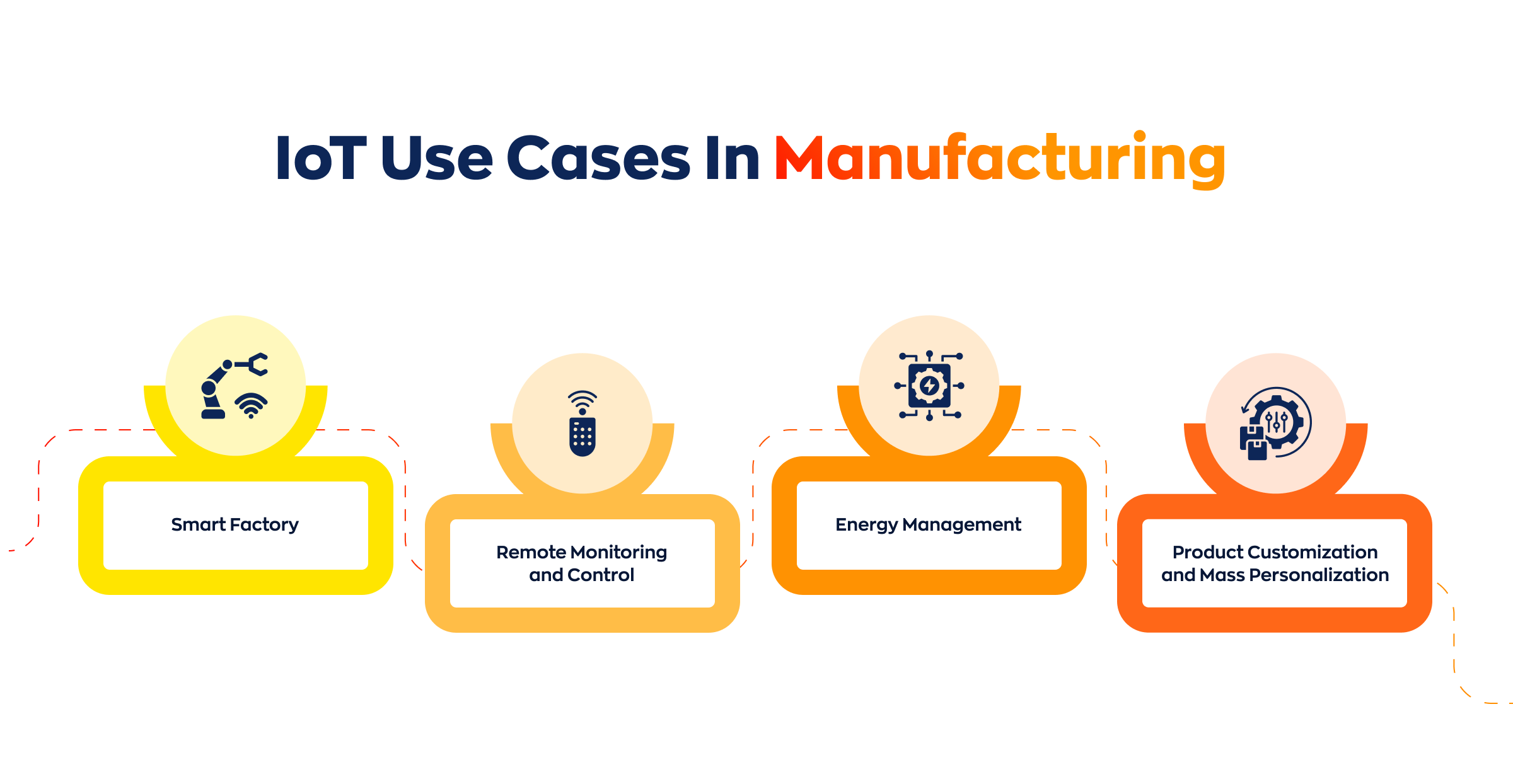

Top IoT Use Cases In Manufacturing

1. Smart Factory

Smart factory is the integration of advanced digital technologies, such as IoT, into manufacturing processes to create highly efficient, automated production environments. These smart factories are characterized by connected machines and systems that communicate with one another to make real-time decisions, optimize processes, and minimize human activity.

Machine-to-Machine (M2M) Communication: A key driver behind smart factory efficiency is machine-to-machine communication. Through M2M, connected devices exchange information without the requirements for human interaction. For example, IoT-enabled machinery can automatically detect when a component is not working and communicate directly with another machine or system to adjust production schedules or trigger maintenance alerts. This real-time communication between devices ensures continuous operations, minimizes bottlenecks, and helps prevent costly downtime.

2. Remote Monitoring and Control

One of the primary advantages of IoT in manufacturing is the ability to remotely monitor and control operations across geographically distributed facilities.

- Centralized Control Across Locations: IoT platforms allow manufacturers to manage production across multiple locations from a single, centralized platform. This provides real-time insights into performance, resource utilization, and productivity without requiring on-site supervision.

- Real-Time Performance Monitoring: IoT sensors constantly monitor equipment, tracking metrics such as temperature, pressure, and vibration. With real-time data, manufacturers can make on-the-spot adjustments to prevent failures and optimize production.

3. Energy Management

Energy consumption represents a significant operational cost for manufacturers, and IoT-based systems are helping optimize energy use.

- Real-Time Energy Monitoring: IoT sensors can track energy consumption in real-time, providing insights into the most energy-intensive machinery and identifying opportunities for efficiency improvements.

- Integration with Renewable Energy Sources: IoT also facilitates the integration of renewable energy sources, such as solar or wind power, into the manufacturing process. IoT-enabled systems can manage the flow of renewable energy, ensuring that it is prioritized when available and switching to the grid when necessary.

4. Product Customization and Mass Personalization

Manufacturers are leveraging IoT to offer mass customization and personalized production without sacrificing efficiency.

- Flexible Manufacturing Systems: IoT enables flexible systems that can quickly adjust production parameters in response to customer demands or market changes.

- Real-Time Adaptation to Customer Requirements: With IoT, manufacturers can gather real-time data on customer preferences and integrate it directly into the production process, allowing for instant adjustments without disrupting the workflow.

Emerging IoT Trends in Manufacturing for 2024 and Beyond

Integration of AI and Machine Learning

The integration of AI and machine learning with IoT is set to revolutionize manufacturing by enabling predictive analytics and autonomous decision-making. Using AI-driven insights, manufacturers can forecast machine failures, maintain optimum maintenance schedules, and automate complex decisions in real-time. The transformative potential of AI in this sector is widely recognized, with one survey finding that 87% of global organizations believe AI technologies will give them a competitive edge.

Key applications include AI-powered quality control, where machine learning algorithms analyze data from IoT sensors to detect defects early and improve product quality. Additionally, AI enhances process optimization by continuously analyzing production data and adjusting operations for maximum efficiency.

This integration seamlessly incorporates the new data into the existing text, providing context for the growing importance of AI in manufacturing and supporting the article's main points about AI's revolutionary impact on the industry.

Use Cases:

Digital Twins and Virtual Simulations

The use of digital twins, which are virtual replicas of physical assets, is growing in the manufacturing industry. These digital simulations enable manufacturers to test, analyze, and optimize products and processes without interrupting actual production. IoT provides real-time data to these digital twins, improving accuracy and helping manufacturers identify potential flaws before they occur in the physical environment.

The implementation of factory digital twins has resulted in cost savings ranging from 5% to 7% monthly for some manufacturers by optimizing production schedules and reducing overtime requirements.

Applications:

- Product design: Simulating new product prototypes in a digital twin environment to identify improvements before physical production begins.

- Process optimization: Testing different manufacturing scenarios to find the most efficient production method.

Overall, digital twins allow manufacturers to simulate production environments and improve quality control, decrease costs, and speed up time to market.

Edge Computing for Faster Data Processing

As IoT devices generate vast amounts of data, the need for faster data processing is critical. This is where edge computing comes into play. By processing data closer to the source, edge computing reduces latency and allows for real-time decision-making, which is crucial in high-speed manufacturing environments. The importance of edge computing is underscored by recent industry forecasts: according to the International Data Corporation (IDC), global spending on edge computing is estimated to reach $228 billion in 2024, a 14% increase from 2023.

Benefits:

- Reduced latency: Data is processed at the network's edge, cutting down the time it takes to transfer information to central servers and back.

- Improved response times: With data processed locally, manufacturers can react faster to potential issues, improving productivity and reducing downtime.

IoT and Augmented Reality (AR)

The combination of IoT and Augmented Reality (AR) is opening new possibilities in maintenance, assembly, and quality control. AR tools, powered by IoT data, offer real-time visual overlays, helping engineers identify issues quickly and offering step-by-step instructions for repairs.

Key Applications:

- Maintenance: AR glasses displaying real-time sensor data from IoT devices can guide workers through complex repairs.

- Assembly: AR interfaces provide detailed instructions for assembly processes, ensuring accuracy and speed.|

- Quality control: IoT sensors detect defects, and AR highlights the areas for inspection.

Case Study: Boeing has integrated AR with IoT to streamline its aircraft manufacturing process. Using AR glasses, workers receive real-time data on assembly tasks, which has improved productivity by 30%.

5G and Advanced Connectivity

The rollout of 5G technology is expected to supercharge IoT capabilities in manufacturing, providing faster and more reliable connectivity for a wide range of devices. With 5G, manufacturers will benefit from enhanced real-time communication between machines, faster data transfer, and the ability to connect more devices simultaneously.

Impact of 5G:

- Real-time data transfer: 5G enables high-speed data transmission, allowing IoT devices to communicate instantaneously and improving overall production speed.

- Improved connectivity: With increased bandwidth, manufacturers can connect more IoT devices, enhancing automation and machine coordination on the factory floor.

Manufacturers leveraging 5G-enabled IoT systems will see improved production line efficiency, better supply chain coordination, and faster product delivery times.

By keeping up with these emerging IoT trends, manufacturers can stay ahead of the competition, boost productivity, and create smarter, more efficient factories. From the integration of AI and digital twins to the advancements in 5G and AR, the future of IoT in manufacturing looks brighter than ever.

Challenges of Implementing IoT in Manufacturing

Despite the immense benefits of IoT in manufacturing, several challenges still impede its widespread adoption. Key issues such as security, data privacy concerns, high implementation costs, and workforce challenges must be addressed to unlock the full potential of IoT-driven manufacturing.

Security and Data Privacy Concerns

One of the most significant challenges for manufacturers implementing IoT is providing the security of connected devices and the vast amounts of data they generate. As the number of IoT-enabled devices grows, so does the potential for cyberattacks. Common security risks include unauthorized access, data breaches, and malware infiltrating IoT networks. Cybersecurity remains one of the main barriers to large-scale IoT adoption in factories, where sensitive operational and production data must be protected from external threats.

To mitigate these risks, manufacturers must adopt robust security measures. Encryption of data both at rest and in transit is essential, as is implementing multifactor authentication (MFA) and strict access control protocols to prevent unauthorized access to IoT networks. Regular software updates and patch management confirm that IoT devices are protected against newly discovered vulnerabilities. Network segmentation is another crucial strategy, isolating IoT systems from the main enterprise network to limit the impact of potential breaches.

Interoperability Issues

Interoperability is a critical limitation in IoT implementation, especially in manufacturing environments that rely on a mix of legacy systems and modern IoT devices. Fragmented IoT ecosystems often result in siloed systems that cannot communicate effectively, leading to inefficiencies and missed opportunities for optimization.

The value of IoT in manufacturing is closely tied to the ability of devices and systems to communicate seamlessly. By 2030, achieving full interoperability across different IoT systems could unlock as much as 74% of IoT’s total value in factories. To address this, manufacturers should adopt open communication protocols such as MQTT, OPC-UA, and CoAP, which facilitate smooth data exchanges between diverse systems. Additionally, standardized APIs can help bridge gaps between legacy infrastructure and newer IoT solutions, enabling smoother integration and more efficient operations.

High Implementation Costs

The high initial costs of IoT implementation are a significant deterrent, especially for small and medium-sized manufacturers. Deploying IoT infrastructure involves investments in hardware, sensors, software, and network upgrades. Moreover, the cost of maintaining and scaling IoT systems can quickly add up, leading many businesses to remain cautious about pursuing full IoT integration. The problem of “pilot purgatory” also arises from this hesitation, with many manufacturers reluctant to move IoT projects beyond the pilot stage because it leads to high installation costs and uncertain returns.

Manufacturers can overcome the cost barrier by moving to cloud-based IoT platforms that will reduce the cost of expensive inside-the-business infrastructure. Phased implementation strategies allow businesses to start with smaller, targeted IoT deployments and scale up gradually. This approach minimizes upfront costs while demonstrating measurable ROI in incremental stages.

For SMBs, IoT platforms offering pay-as-you-go pricing models provide a cost-effective way to access advanced IoT capabilities without a heavy investment burden. Manufacturers can justify the investment through tangible cost savings and increased efficiency by carefully analyzing the ROI of individual use cases, such as predictive maintenance.

Skill Gap and Workforce Training

Last but not least, the challenge in adopting IoT in manufacturing is the skills gap. Many workers need more expertise in data analytics, cybersecurity, and network management, which has slowed IoT adoption. To overcome this, manufacturers need to focus on upskilling and reskilling their workforce through on-the-job training programs that cover IoT system operations and data analysis.

Additionally, partnering with educational institutions and IoT training providers can help create a pipeline of skilled workers with the technical expertise required to operate, maintain, and secure IoT-enabled systems.

Choosing the right IoT Solution Provider

Selecting the right IoT solution provider is a crucial decision that can significantly impact the success of your IoT implementation. As manufacturing processes continue to advance and rely more on IoT technologies, it's crucial to have a partner who understands both the technology and your industry. The ideal provider will guarantee that your IoT solutions are scalable, secure, and customized to meet your specific operational requirements, all while providing continuous support and guidance.

It’s important to note, that making the wrong choice could lead to costly downtime, integration issues, or security vulnerabilities. That’s why it’s necessary to evaluate key metrics when choosing your IoT partner carefully.

Key Benefits of Choosing the Right IoT Provider

When selecting an IoT provider, consider the following critical benefits that will set your business up for success:

- Scalability: The provider should offer solutions that can grow alongside your business, accommodating increased data volumes and new operational needs without rebuilding your infrastructure.

- Service Quality and Support: Reliable support is essential to avoid disruptions. A provider with a strong reputation for customer service will help you keep your IoT system running smoothly and quickly address technical issues.

- Tailored Solutions: Every manufacturing environment is unique. Your provider should offer customized IoT solutions that meet your specific requirements, whether you’re looking to implement predictive maintenance, automate production lines, or monitor energy usage.

- Security Expertise: As IoT ecosystems grow, so do the risks. A provider with a focus on robust data security ensures your systems and information are protected from cyber threats and unauthorized access.

- Industry-Specific Experience: Working with a provider that has deep manufacturing experience means they understand your unique challenges — from regulations to legacy system integration.

Why Aionys is the Right IoT Partner for Your Manufacturing Needs

At Aionys, we understand the unique demands of the manufacturing industry. Our approach is centered on delivering tailored IoT solutions that meet the specific challenges you face, ensuring smooth integration and long-term growth.

When you choose us, you benefit from the:

1. Scalable Solutions for Long-Term Growth

Your IoT solutions must grow with your manufacturing business. No matter if you’re just beginning with small-scale applications or beginning full factory automation, we design scalable IoT systems that grow with your operations. Our systems have been designed to accommodate increased data volumes, new production lines, and expanding requirements, and seamlessly integrate with zero cost to the infrastructure upgrades.

2. Comprehensive Support and Service Quality

Manufacturing operations cannot afford disruptions. That's why we offer exceptional, proactive support to guarantee that your IoT systems run smoothly at all times. Our team provides continuous monitoring, predictive maintenance, and rapid issue resolution to identify and solve any potential technical problems before they affect your operations.

3. Tailored IoT Solutions Built for Your Specific Needs

Every manufacturer is different, just like every business. That's why we at Aionys don't believe in cookie-cutter IoT solutions. We work with you to build a system that's tailored to your exact needs. Whether you want to predict when machines might break down, automate your production, or keep an eye on your energy use, we've got you covered. Our goal is simple: to make your factory smarter, more efficient, and more profitable.

4. High-Level Security

When it comes to IoT, security is a big deal. As more and more devices get connected, the risk of cyberattacks also grows. That's why we take security seriously. Every IoT solution we build is designed with protection in mind. We use the latest security tech to keep your data and systems safe from hackers and other bad guys. So you can focus on running your business without worrying about getting hacked.

5. Industry-Specific Expertise in Manufacturing

We've been working in manufacturing for a long time. We know the ins and outs of the industry, from the challenges you face to the rules you have to follow. Furthermore, we can help you integrate new IoT technology with your existing systems, and we'll make sure everything complies with industry standards. The main goal is to make your operations smoother and more efficient so you can focus on what you do best

Take the next step in unlocking the full potential of IoT in your manufacturing processes. Contact us today to discover how we can help you scale, optimize, and secure your manufacturing operations for long-term growth and success.

Conclusion

The Internet of Things (IoT) is no longer a futuristic concept; it's a present-day necessity for manufacturers aiming to stay competitive. From small and medium-sized businesses to large enterprises, IoT offers the tools to optimize operations, reduce costs, and improve product quality.

Whether you're looking to predict equipment failures, automate processes, or enhance supply chain visibility, IoT can transform every aspect of your manufacturing operations. By leveraging data-driven insights and connected technologies, you can streamline workflows, minimize downtime, and deliver exceptional products and services.

The future of manufacturing is digital. By embracing IoT, you can position your business for long-term growth, innovation, and success. Discover how IoT can transform your manufacturing.